Polycarbonate is a lightweight material with the highest impact strength; so much so that it’s almost unbreakable. In contrast to the majority of thermoplastics, polycarbonate can withstand large plastic deformations without breaking, or even cracking.

This allows it be processed and formed at room temperature. The downside is its low scratch resistance.

What Are The Different Types of Polycarbonate?

Polycarbonate was developed in the middle 20th century by GE in the United States and Bayer in Germany. Today it is manufactured by a large number of firms, each typically with their own production process. Trade names include well known variants like Lexan®, or Makrolon®. With more locally known trade names being Palsun, Suntuf and Ampelite.

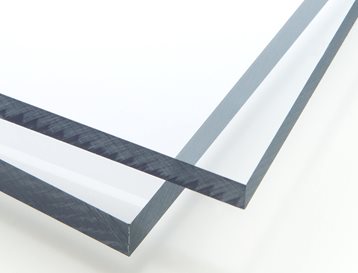

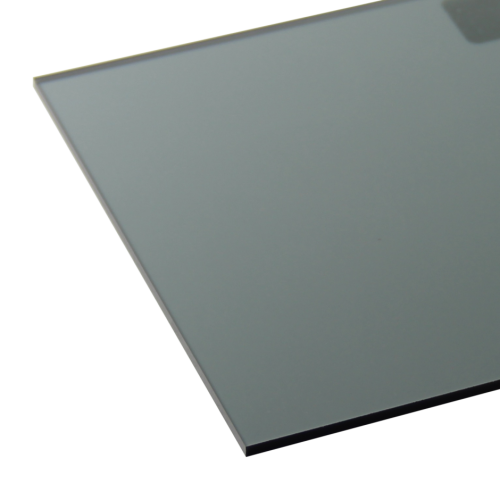

There are various industry grades available. Most are called by the generic name (polycarbonate) and are typically differentiated by the amount of glass fiber reinforcing they contain and some polycarbonates have additives such as “ultraviolet stabilizers” that protect the material from long-term sun exposure. Finished polycarbonate is typically sold in solid sheets, twin wall sheets, rods or tubes.

What is Polycarbonate Used For?

Polycarbonate is used to produce a variety of material types and are particularly useful when impact resistance are a requirement (e.g. in bullet-proof glass). Some uses for the material include machine guards, eyewear products, windows, electronics and outdoor lighting fixtures.