Description

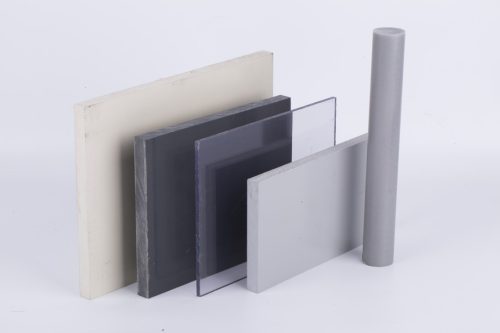

UHMWPE (Ultra-High Molecular Weight Polyethylene) sheet is a type of thermoplastic, it is known for its exceptional strength, durability, and resistance to abrasion and impact. This makes it suitable for use in a wide range of industrial and medical applications, such as gears, bearings, rollers, wear strips, conveyor components, and medical implants such as artificial joints and spinal disks. These sheets have self-lubricating properties, are lightweight, chemical and UV resistant, and can withstand a wide range of temperatures.

Features:

- Extremely durable and resistant to abrasion and impact: UHMWPE sheets have an incredibly high molecular weight, making them exceptionally strong and resistant to wear and tear. This makes them perfect for applications that require prolonged use and exposure to harsh conditions.

- Self-lubricating: UHMWPE sheets have a low coefficient of friction, which means that they do not require external lubrication. This feature reduces friction and wear, extending the lifespan of the sheets and reducing maintenance costs.

- Lightweight: the material is lightweight and easy to handle, making them ideal for applications that require frequent transport or movement.

- Chemical and UV resistant: UHMWPE sheets are resistant to a wide range of chemicals and UV rays, making them suitable for use in environments where exposure to these elements is a concern.

- Temperature resistance: these sheets can withstand temperatures from -269°C to 80°C, making them suitable for use in a wide range of temperatures.

Potential Applications:

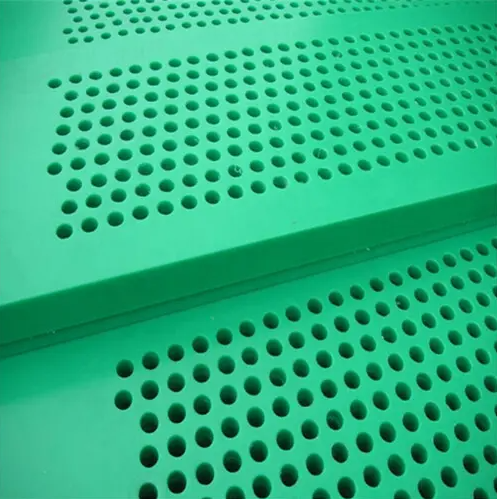

- Wear strips and conveyor components: UHMWPE sheets are perfect for use as wear strips and conveyor components due to their abrasion and impact resistance. This makes them ideal for use in industries such as mining, manufacturing, and transportation.

- Gears, bearings, and rollers: UHMWPE sheets can be used to make gears, bearings, and rollers that require less maintenance and are more durable than those made from other materials.

- Line chutes and hopper liners: UHMWPE sheets can be used as liners in chutes and hoppers to reduce friction and wear, and improve material flow.

- Sliding surfaces and machinery parts: the material can be used for sliding surfaces and machinery parts that need to be lubricated and resist abrasion, corrosion and impact.

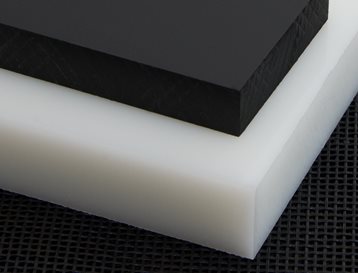

Available Colors:

- Natural (white)

- Black

- Custom colors available upon request

FAQ:

Q: What is UHMWPE used for?

A: It is used in a variety of industrial and medical applications such as gears, bearings, rollers, wear strips, conveyor components, and medical implants such as artificial joints and spinal disks.

Q: Is UHMWPE stronger than steel?

A: UHMWPE fibres have and incredibly high tensile strength compared to other materials, including steel in the fibre direction. The tensile strength of high-strength steel is approx. 900 MPa, but in order to break the fibres in UHMWPE, you need approximately 3000 MPa.

Q: Is UHMWPE stronger than Kevlar?

A: It can be stronger than steel but not as strong as Kevlar.

Q: What is UHMWPE material?

A: Ultra-high molecular weight polyethylene. It is a thermoplastic material that has a wide range of industrial and medical applications.

They are perfect for any application that requires extreme durability and resistance to wear and tear.