CNC Laser Cutting Services for Plastics in Sydney.

At KF Plastics, our plastic laser cutting services are designed to deliver unmatched precision and intricacy across a wide variety of materials. Whether you need complex designs, standardised components, or custom creations, we have the expertise and technology to bring your vision to life with impeccable detail and efficiency.

If you’d like to explore how laser cutting achieves such accuracy and versatility, read our articles How Laser Cutting Delivers Precision Acrylic Parts for Sydney Retail Displays and Unlocking the Potential of Laser Cutting: Innovations, Applications, and Choosing the Right Service. These guides provide insights into the technology, techniques, and real-world results behind our work.

Why Choose KF Plastics for Laser Cutting plastic?

High Precision and Consistency:

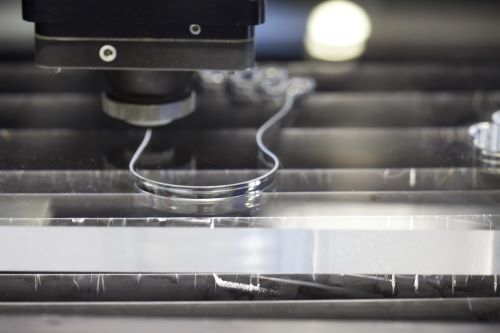

Our state-of-the-art CNC laser cutters ensure each cut is sharp, clean, and consistent, providing exact results across multiple pieces. This level of precision ensures your projects meet the tightest tolerances and highest quality standards.

Fast Turnaround Times

With advanced machinery and optimized processes, we offer quick production times without sacrificing quality. Even for complex jobs, we work efficiently to help you meet tight deadlines.

Custom and Complex Designs

From intricate patterns to custom shapes, our CNC laser cutters handle even the most detailed designs. Whether your project requires high precision or personalized creativity, we tailor our solutions to meet your unique needs.

How Our CNC Laser Cutting Process Works at KF Plastics

At KF Plastics, our Sydney-based laser cutting process is streamlined for efficiency, precision, and client satisfaction. From initial consultation to final delivery, we ensure every step aligns with your project needs. Here’s a breakdown:

Step 1: Design Consultation and File Preparation

We start with a consultation to understand your project. Whether it’s a simple signage cut or complex architectural prototype. Upload your designs via our request a quote form file upload or email. We accept vector files like .AI, .EPS, .DXF, .DWG, STEP, or .SVG (as noted in our FAQ). Our team reviews for compatibility, suggests optimisations (e.g., adjusting for material thickness), and handles some conversions if needed. If you do not have vector artwork, we offer design assistance for a small fee depending on complexity, ensuring paths are vectorized for clean cuts.

Step 2: Material Selection and Setup

Based on your requirements (e.g., durability for outdoor signage or product fit for retail displays), we recommend from our wide range of materials like acrylic for high gloss finishes or PETG for impact resistance. We source high quality sheets in house, set up the machine and toolpath program with precise parameters (e.g., laser power, speed, and focus settings), and perform test cuts on scrap material to calibrate for perfection. This step minimises waste and ensures a good quality cut and is within cutting tolerances.

Step 3: Precision Cutting and Finishing

Our advanced CNC lasers (more on equipment below) execute the cuts with a high level of accuracy, handling intricate details without damage. The process is automated for consistency across batches, with constant monitoring to catch any issues. Post-cutting, we can provide additional services including line bending, thermoforming or engraving for added detail.

Step 4: Quality Control and Delivery

Every piece undergoes inspection for tolerances, edges, and defects. We package securely and offer fast Sydney delivery (3-5 days standard) or pickup. If adjustments are needed, we iterate quickly. This process supports everything from prototyping to large-scale manufacturing, with fast turnarounds for urgent jobs.

Applications of Our CNC Laser Cutting Services

Signage and Display:

We create detailed, eye-catching signage for businesses, events, and promotions. From storefront signs to logos and event displays, our laser cutting technology ensures crisp edges and durable finishes, helping your brand stand out.

Architectural Features:

Our precision plastic laser cutting service is perfect for crafting architectural elements such as decorative panels, custom railings, and facades. Whether for interior or exterior projects, we deliver beautiful, high-quality results.

Retail and Point of Sale Displays:

Enhance your retail space with custom-designed displays, brochure holders, and stock stands. With precision cutting, we produce visually appealing, functional displays that engage customers and boost your brand’s visibility. For more inspiration, read our article How Laser Cutting Delivers Precision Acrylic Parts for Sydney Retail Displays — a deep dive into how retailers are using laser-cut acrylic to transform their visual merchandising.

Office and Retail Interiors:

For unique office and retail interiors, our laser cutting services provide custom solutions including feature walls, partitions, lighting fixtures, and bespoke furniture. Let us help you create a space that’s both functional and striking.

Component Manufacturing:

For industries that require precision components, we offer laser cutting with tight tolerances. This service is ideal for sectors like electronics, automotive, aerospace, and medical devices, where accuracy is paramount.

Prototyping and Product Development:

Laser cutting is ideal for prototyping and product development, offering fast turnaround times and detailed designs. Whether you need a single prototype or small batch production, we bring your concepts to life efficiently.

Artistic and Decorative Projects:

Artists and designers rely on our laser cutting services to produce detailed decorative pieces, including custom artwork, sculptures, and engravings. Our precision ensures your artistic vision is captured in stunning detail.

Educational and Research Projects:

We collaborate with educational institutions and research facilities, offering precision-cut components for academic and experimental projects. From teaching aids to detailed models, our services support your innovative research.

Lighting Applications:

Create custom lighting solutions with our laser cutting capabilities. From intricate lampshades to decorative light panels, our precision technology enhances the visual appeal and functionality of your lighting projects.

Fashion and Textiles:

In the fashion industry, our laser cutting technology produces intricate patterns on fabrics, leather, and textiles. We help fashion designers craft custom garments, accessories, and unique decorative elements with precision.

Model Making and Prototyping:

Whether you’re an architect, model maker, or hobbyist, our laser cutting services provide the precision needed for architectural models, scale models, and replicas. Achieve professional-grade results with ease.

Materials We Work With

Our laser cutting technology handles a broad range of materials, including:

| Acrylic | Plywood | MDF |

| Veneer | PETG | Polypropylene (PP) |

| Cardboard | Acrylic Mirror |

Customer Testimonials

The lady, Geeta at the front desk is really supportive and helpful.

They cut panels on the spot whatever sizes needed. If you urgently need perspex to cut, this is a right place to be.

Highly recommend.

Fantastic company to work with, professional and helpful staff

Quick turnaround and they were able to cut sheets on the spot within a few minutes. Staff were really friendly and professional, and the prices were fair.

Ready to Elevate Your Project with Laser Cutting?

Contact us today to learn how our CNC laser cutting services can help bring your project to life. Whether you need precision components or intricate custom designs, KF Plastics delivers quality you can trust.

Frequently Asked Questions About Laser Cutting

Clean with a mild soapy warm water solution using a soft cloth or sponge. Never use window cleaners (like Windex) or abrasive scouring pads, as these will damage the surface. For best results, use a specialized plastic polish like our antistatic cleaner. For a complete step-by-step guide and expert tips, please read our full article on How to Clean Acrylic Sheet: A Guide to Maintenance and Care

Acrylic is 50% lighter than glass and has much higher impact resistance. It also offers better optical clarity, transmitting 92% of visible light compared to glass’s 90%.

There is no actual difference in the material. Perspex® is a brand name for acrylic (polymethyl methacrylate). Whether you call it Acrylic, Perspex, or Plexiglass, you are referring to the same high-quality plastic.

While they look identical, they have different properties. Cast Acrylic is made by pouring liquid into a mould. It is harder, better for machining and laser cutting (it engraves white), but has slightly variable thickness tolerances. Extruded Acrylic is pushed through rollers. It has very consistent thickness and is cheaper to make in markets of high demand, making it ideal for glazing, but it can melt if laser cut or drilled at high speeds. We primarily stock Cast Acrylic for its superior fabrication qualities

Turnaround depends on job size, but most small to medium runs are ready within 3–5 business days. Rush jobs can often be arranged, just contact us to confirm lead time.

Absolutely. Our team can check and prepare your files for cutting, ensuring proper line weights, spacing, and vector paths. We can also convert your design to a suitable laser ready format if required (charge may apply).

We specialise in plastic laser cutting, including acrylic (Perspex), PETG, MDF (for push through signage) and polypropylene. We also engrave certain coated metals and laminates, depending on the project requirements.

Our laser can cut acrylic and Perspex up to 25 mm thick with smooth, flame-polished edges. For thicker materials or other plastics, we can advise whether CNC routing is a better option.

We accept vector files such as .AI, .EPS, .DXF, .DWG, STEP and .SVG. PDF and high resolution .JPEG files can also be used for reference, but vector artwork gives the best precision and cut quality.